Address

5th Floor, No.77 Xinhe Rd, Shangmugu, Pinghu Area, Longgang District, Shenzhen, Guangdong, China

Contact

Email [email protected]

Tell (+86) 755-25507076

5th Floor, No.77 Xinhe Rd, Shangmugu, Pinghu Area, Longgang District, Shenzhen, Guangdong, China

Email [email protected]

Tell (+86) 755-25507076

More people are recognizing the importance of understanding battery internal resistance in daily usage. In our previous article, we discussed how internal resistance affects batteries. For users without professional equipment, determining battery internal resistance may seem challenging.

This article will guide you on easily testing battery internal resistance, improving measurement accuracy, and interpreting battery health based on internal resistance values.

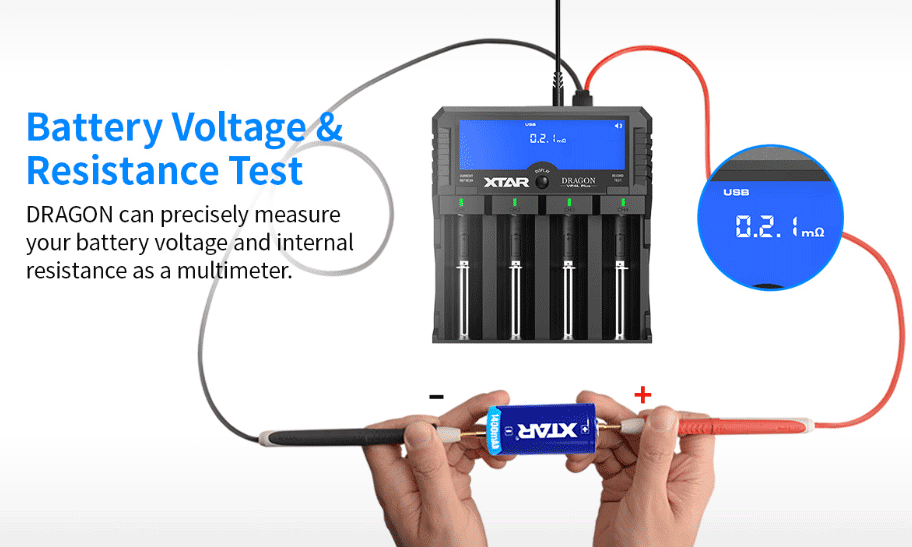

While there are battery testers in the market, their accuracy is questionable. To simplify internal resistance assessment, intelligent chargers with testing features are available. XTAR, a renowned manufacturer, has produced chargers with an internal resistance testing function.

XTAR chargers with this function can be categorized into two types:

● Test in charger slots: After inserting the batteries into the charger slots, the charger will automatically test the battery internal resistance. A single click of the Mode button enables you to effortlessly check the value. This way is used in the XTAR VC series, including VC2SL, VC4SL, VC8, and the latest VC8S charger.

● Test with external probes: Connect the probe to the charger and short-circuit the positive and negative poles. Touch the probe poles to the terminals of the battery, then read the test value. This method is used in the XTAR VP4L PLUS.

Test in charger slots is easier. But with external probes would get higher accuracy. It tests like a multimeter. This is because probe testing employs a four-wire method, effectively eliminating inherent resistance in the charger and probe leads, thereby minimizing the impact of line resistance on the tested battery. While the test in charger slots uses a two-wire method. It needs to consider the internal resistance deviation in charger and the terminal contact. This method has more uncertainty.

The test of internal resistance includes AC internal resistance(ACIR) and DC internal resistance(DCIR). The ACIR is usually tested with an impedance analyzer. The DCIR can be measured with a battery tester. We adopt DCIR test method. The test principle of DC resistance is to apply a large current (charge or discharge) to the battery for a short time and then measure the voltage change of the battery. There are four parameters related: current, pulse time, SOC, and ambient temperature.These parameters have great influence on IR accuracy. Here are 5 aspects to consider in enhancing the accuracy.

● When measuring internal resistance in charging method, the optimal voltage range for Ni- MH batteries is between 1.3V and 1.4V. While for Li-ion batteries, it is between 3.6V and 3.8V. Testing internal resistance at these voltage states generally yields more accurate results. For Li-ion batteries, testing is not conducted if the voltage exceeds 4.1V, to prevent overcharging and potential battery damage.

● When measuring internal resistance in discharge method, even fully charged batteries can be tested. The discharging method is more accurate than charging method in DCIR test. The resistance will not be tested under the condition of Ni-MH batteries with voltages below 1V and Li-ion batteries below 3V. This is due to the risk of over-discharging and the low cell activity, which may result in inaccurate readings and higher internal resistance values. Currently, most of XTAR chargers adopt discharging test method.

● Battery terminals, typically made of metal, may oxidize, corrode, or gather dirt when exposed to air. This can impede current flow or increase internal resistance. Prior to testing, wiping the battery’s surface and terminals with alcohol can yield more reliable results.

● To get a accurate internal resistance, ensure a good connection between the battery and the charger’s positive and negative terminals or external probe ports. Poor contact may disrupt current flow and lead to significant deviations in the measured internal resistance.

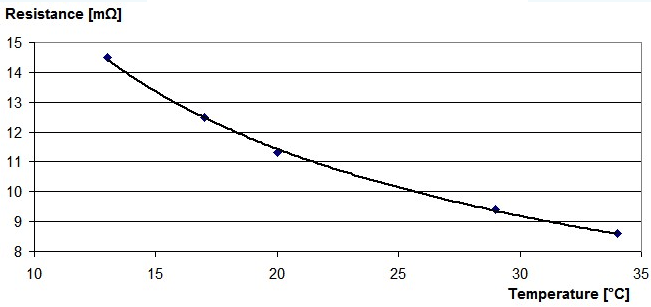

● As mentioned in the previous article, battery internal resistance is affected by temperature variations. Therefore, it’s crucial to control the environmental temperature during testing. Testing conducted within room temperatures ranging from 20℃ to 25℃ typically yields relatively stable results, enhancing the test accuracy.

Ideally, a battery’s internal resistance should be zero to ensure maximum current flow without energy loss. However, in reality, internal resistance always exists. The internal resistance affects the battery’s current-carrying capacity. The higher the internal resistance, the greater the energy loss. This not only results in energy wastage but also contributes to battery degradation.

So, What should be the internal resistance for high-quality batteries? Depending on materials, structure, size, voltage, and other factors, different battery types have varying internal resistances. Here are references for three common battery models in daily life:

● Li-ion Battery: Generally, a healthy lithium ion battery should have an internal resistance of less than 20mΩ. A well-performing 18650 high-drain battery typically has an internal resistance of around 12mΩ, The internal resistance of protected lithium ion batteries is below 70 mΩ. A healthy 16340 protected battery should have an internal resistance around 120mΩ.

● Ni-MH Battery: A healthy Ni-MH battery usually has an internal resistance of less than 50mΩ. Ni-MH high-drain battery tend to have internal resistances between 10-20mΩ, while a AAA Ni-MH battery performs relatively well with an internal resistance around 35mΩ.

● Alkaline Battery: A healthy AA alkaline battery might have an internal resistance of around 100mΩ, gradually increasing to several hundred ohms with extended usage.

The values mentioned above are for reference only. It’s advisable to consult the data provided by the manufacturer.

Typically, lower internal resistance in batteries indicates better discharge capabilities, as it suggests the battery can provide more power and has a longer lifespan. However, does higher internal resistance mean worse battery? Not necessarily. A battery with high internal resistance isn’t necessarily ‘failed.’ Some batteries with high internal resistance perform well during low-current discharges but struggle to maintain stable output at high currents, unlike new batteries. When the internal resistance exceeds twice the initial value, it’s recommended to reduce its usage and keep the discharge rate below 0.5C. You can consider using it for low-power devices with lower current consumption.

It’s important to note that internal resistance is just one of many factors affecting battery performance and lifespan. Other factors also play significant roles, such as capacity, temperature, and the number of charge-discharge cycles .

In evaluating battery health, even without testing internal resistance, we can assess the battery’s condition through simple observation and usage experience. Here are some convenient methods:

● Carefully inspect the battery for deformities, leaks, or damages. These signs might indicate the battery has failed.

● Some batteries might produce buzzing or unusual sounds during operation, which could be indicative of issues.

● Observe the performance of devices using the battery. Frequent power cuts or significant performance degradation could signify battery problems.

● Under the same working conditions, if the battery’s temperature rises rapidly and becomes unusually hot while depleting quickly, it might indicate that the internal resistance has increased to a near-failure level.

When you read here, you’ve already know the easy way to test the battery internal resistance, how to enhance the accuracy and how to judge the battery health. Now, it’s time to take action! Choose a suitable charger and test the health of your batteries.